As a leading supplier of specialty chemicals, we understand the importance of selecting the right surfactant concentration for your formulations. Sodium Laureth Sulfate (SLES) is one of the most widely used anionic surfactants in the personal care and cleaning industries. This detailed comparison will help you understand the key differences between SLES 70%, 60%, and 55% concentrations to optimize your product development.

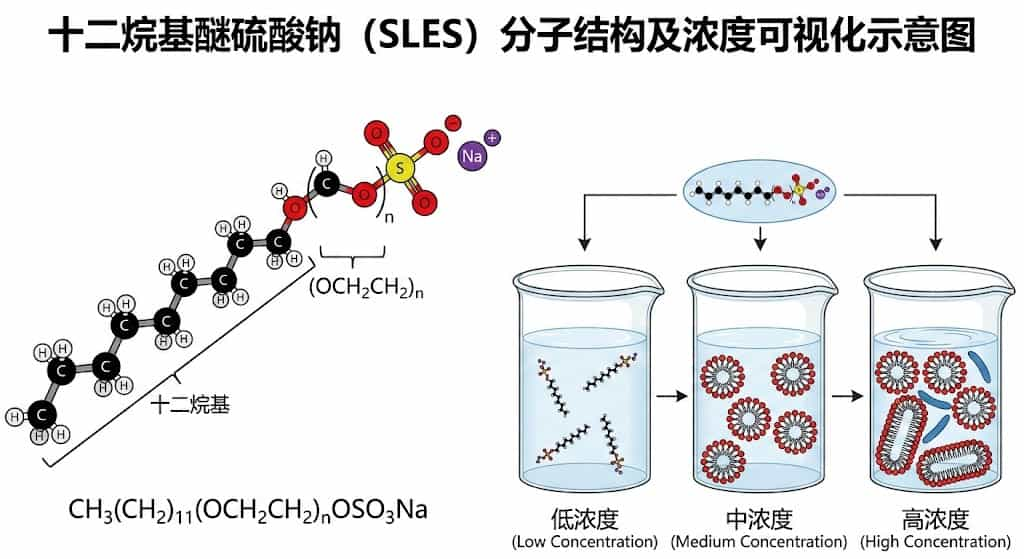

Sodium Laureth Sulfate (SLES) is an anionic surfactant derived from coconut oil or palm kernel oil. It’s known for its excellent foaming, cleansing, and emulsifying properties. The percentage values (70%, 60%, 55%) refer to the active content of SLES in the aqueous solution, with the remainder being water and sometimes small amounts of salts or impurities.

| Property | SLES 70% | SLES 60% | SLES 55% |

|---|---|---|---|

| Active Content | 70% ± 2% | 60% ± 2% | 55% ± 2% |

| Water Content | Approximately 30% | Approximately 40% | Approximately 45% |

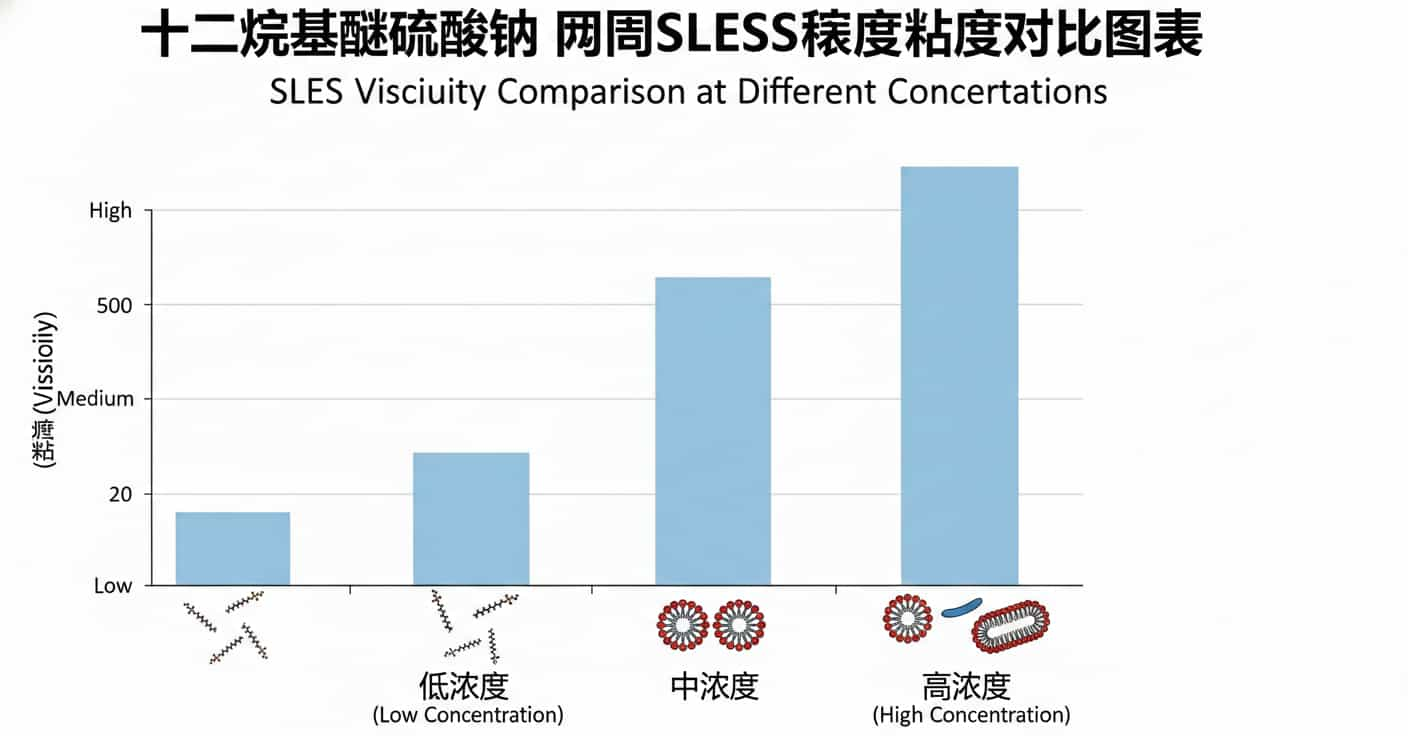

| Viscosity (at 25°C) | 200-500 mPa·s | 100-300 mPa·s | 50-150 mPa·s |

| Appearance | Clear to slightly hazy viscous liquid | Clear to slightly hazy liquid | Clear liquid |

| Color | Colorless to pale yellow | Colorless to pale yellow | Colorless to pale yellow |

| pH (10% solution) | 7.0-9.0 | 7.0-9.0 | 7.0-9.0 |

| Density (g/cm³) | 1.05-1.10 | 1.05-1.10 | 1.05-1.10 |

| Primary Applications | High-foaming products, concentrated formulations | General-purpose cleaners, shampoos | Light-duty cleaners, sensitive skin formulations |

Highest active content with maximum viscosity. Ideal for formulations requiring minimal water content or where transportation costs are a concern. Provides superior foaming power and cleaning efficiency in concentrated products.

Key Advantage: Cost-effective for shipping, high performance in small doses.

The most commonly used concentration in the industry. Offers balanced viscosity and handling properties. Suitable for a wide range of applications from personal care to industrial cleaners. Easier to pump and mix than 70% solutions.

Key Advantage: Versatile, easy to handle, industry standard.

Lower viscosity makes it ideal for automated dispensing systems and formulations requiring easy flow properties. Often preferred for products targeting sensitive skin due to slightly lower active content.

Key Advantage: Easy handling, suitable for sensitive formulations.

Choose SLES 70% if: You need maximum active content for concentrated formulations, want to minimize shipping costs, or require high viscosity for product stability. Best for industrial applications and products where water content needs to be minimized.

Choose SLES 60% if: You need a versatile, industry-standard surfactant for general-purpose applications. This concentration offers the best balance of performance, handling, and cost for most personal care and cleaning products.

Choose SLES 55% if: You require easier handling with lower viscosity, are formulating for sensitive skin, or need compatibility with automated manufacturing systems. Also suitable when slightly milder cleansing is desired.

When formulating with different SLES concentrations, consider these factors:

All our SLES products meet stringent quality standards with consistent batch-to-batch quality. We recommend:

Last updated: [2025-01-21 14:56:58] | Author: Clean Chemical Specialists

Copyright © 2013 ZHENGZHOU CLEAN CHEMICAL CO.,LTD